CEDEX News

CEDEX Debuts at ProMat 2025, Showcasing AI-Powered Container Loading and Cross-Border Collaboration

3/21/25

From March 17 to 20, 2025, ProMat—North America’s leading supply chain and logistics technology exhibition—was held in Chicago, bringing together over a thousand companies from around the world.

Exhibits covered cutting-edge areas such as automation, robotics, and enterprise software. After attending ProMat and MODEX for two consecutive years as a visitor, CEDEX (China Enterprise Data Exchange) made its official debut this year as an exhibitor in the Lakeside section, launching its in-house developed intelligent container loading solution: Whale Stack.

Whale Stack was designed to address challenges emerging in the post-pandemic logistics landscape, such as rising container costs and declining loading efficiency. It integrates machine learning algorithms with human-adjustable logic, enabling both one-click optimization and flexible control. As one of CEDEX’s core explorations in "AI + Logistics", Whale Stack is evolving toward a higher level of automation—future versions are envisioned to interface directly with autonomous forklifts and robotic handling systems, creating an end-to-end workflow from AI-driven layout to robotic execution. This aims to fundamentally transform the labor-intensive nature of traditional container loading and drive a step-change in global logistics efficiency.

During the show, CEDEX held in-depth discussions with Tony D’Angelo, CSO of our North American partner Loren Data, covering the development of EDI/API standards, data interoperability practices, and future cooperation opportunities between China and the U.S. Both sides expressed a shared commitment to improving cross-border system connectivity for manufacturing and retail clients and explored new directions for integrated service delivery.

This year’s ProMat underscored the accelerating shift in logistics toward intelligence, low-labor operations, and flexible collaboration. The prominence of automation equipment, digital twin platforms, and AI-powered systems validated CEDEX’s strategic focus on data-driven intelligent logistics. More than a product showcase, this debut marks a significant milestone in CEDEX’s global expansion.

Executive-Level Engagement Between CEDEX and PipeChain in February 2025

3/1/25

Following the October 2024 visit of PipeChain Network’s new CEO, Agneta Lund, to CEDEX, Mr. Mingguang Cheng, CEO of CEDEX, conducted a business visit to Sweden. As a global leader in EDI (Electronic Data Interchange) and API-based data transmission services, CEDEX has maintained a deep 13-year partnership with PipeChain in the automotive and retail industries, jointly serving world-renowned buyers such as Volvo and IKEA while facilitating hundreds of Chinese suppliers in efficiently connecting with the global market.

During this visit, both parties engaged with key business partners and held in-depth discussions with Swedish enterprises, including Biltema, AB Volvo, IKEA, Odette Sweden, and Monitor ERP. These discussions provided valuable insights into their supply chain digitalization strategies, order management needs, e-invoicing, logistics collaboration, and the evolving industry landscape driven by AI technologies. CEDEX updates its Swedish partners the latest advancements in China’s manufacturing supply chain digitalization, EDI/API innovations, and AI applications, and sharing the challenges and opportunities faced by Chinese manufacturers in operating digitalized supply chains.

In addition to these partner meetings, Mr. Cheng held strategic discussions with key executives from PipeChain, including Hans Berggren (CEO, PipeChain Group), Agneta Lund (CEO, PipeChain Network), Johan Alm (Development Director), Mikael Johansson (Director of International Cooperation), and Jens Dremo (CEO, PipeChain SCM). The discussions focused on leveraging the Network Alliance (NA) framework to deepen business collaboration in response to rapid AI advancements.

CEDEX sincerely appreciates PipeChain’s warm hospitality during this visit. Both teams will work closely together to progressively achieve the business objectives established during these high-level discussions. Moving forward, CEDEX and PipeChain will continue to reinforce their executive-level engagements in alignment with business development needs.

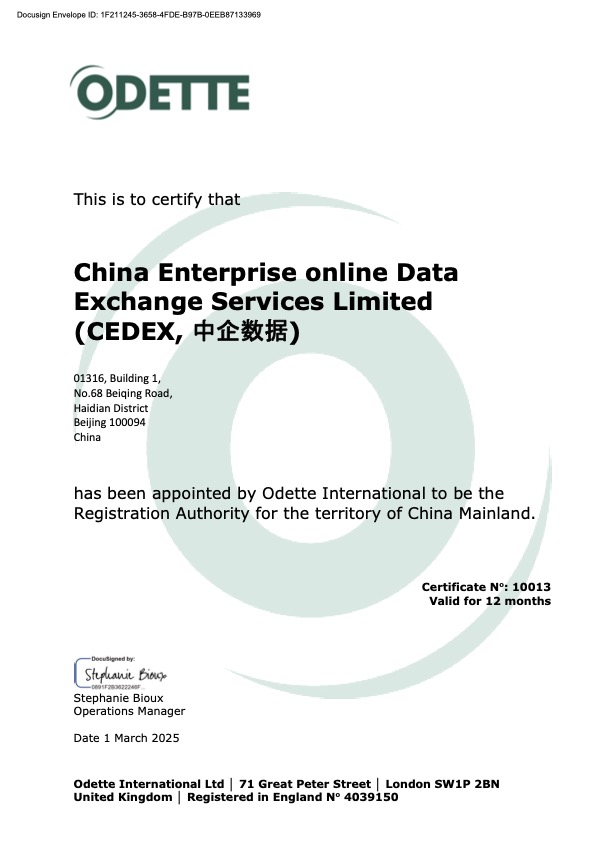

CEDEX and Odette Mark the 12th Year of Partnership

2/28/25

In 2025, CEDEX enters its 12th year of partnership with Odette CA, once again receiving authorization as a Regional Registration Authority (RA) for Odette CA in China. Odette CA is a globally recognized provider of digital identity and electronic signature certificates for secure data transmission in the automotive industry.

As the exclusive Odette CA Registration Authority in China, CEDEX continues to manage certificate registration, technical support, and market development. Over the past years, CEDEX has enabled thousands of Chinese automotive suppliers to securely and reliably transmit sensitive business data over the public internet, ensuring data integrity, authenticity, and compliance with international standards.

With the rapid digital transformation of China's automotive industry, CEDEX remains committed to strengthening global supply chain connectivity through secure and efficient data transmission solutions.

2024 CEDEX Team building on Cruise

9/7/24

From August 29 to September 3, 2024, CEDEX embarked on a 6-day team-building journey aboard the Royal Caribbean Spectrum of the Sea. The trip celebrated the company’s growth since its founding in 2005 and set a vision for future development.

The purpose of this cruise was to allow the team to experience world-class service firsthand and apply those insights to CEDEX’s digital supply chain services. The team enjoyed top-tier facilities, reflecting on how exceptional service can be integrated into daily operations.

During a strategy meeting on September 2, the management team reviewed CEDEX's growth and discussed future plans. Looking ahead, CEDEX will continue supporting local businesses while expanding globally through supply chain digitization. The company remains committed to investing in new technologies and providing efficient, high-quality solutions to its clients.

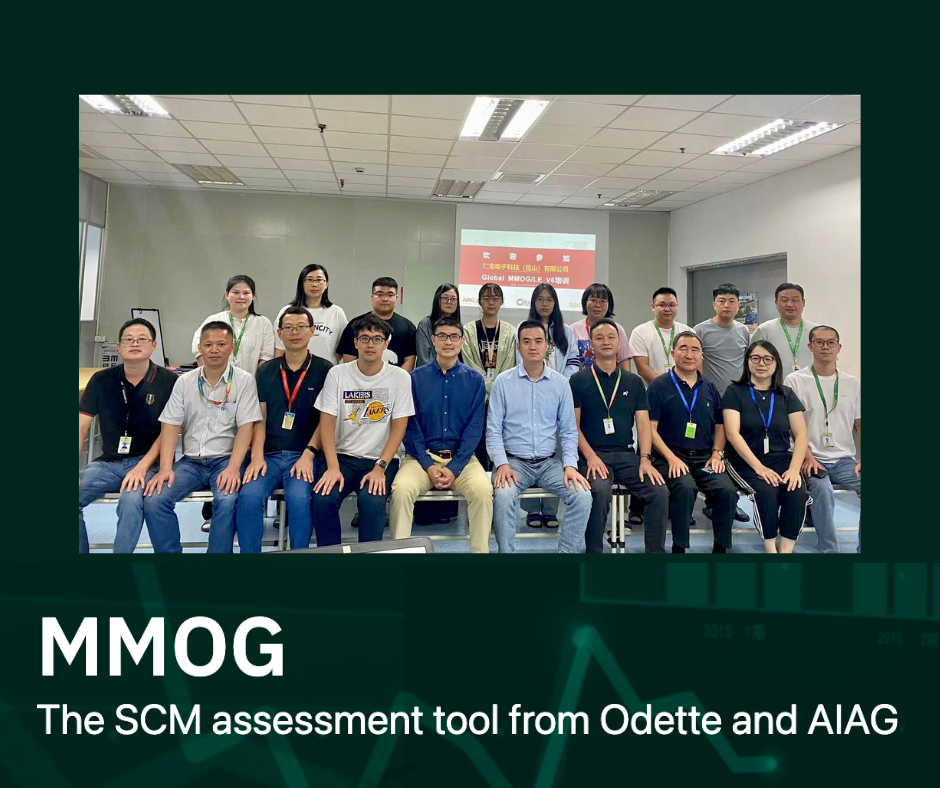

2024 Global MMOG/LE v6 (Chinese) Summer Workshop at Wuhan

6/1/24

From May 31 to June 1, 2024, the Global MMOG/LE V6 (Chinese) Summer Training Course was held in Wuhan, hosted by CEDEX. The training session was organized in a small class for the effectiveness of the training and to provide an opportunity to practice online reviewing on MMOG reviewing platform.

There were eight representatives from supplier companies such as Pryde Automotive Technology (Suzhou) Co., Ltd. and Ningbo Fengmei Technology, as well as two reviewers from Ford Motor. Through the training, the supplier representatives gained a deeper and more comprehensive understanding of the MMOG/LE , also practise for the online evaluation, and had in-depth exchanges with the OEM evaluators. All eight reviewers who participated in this small-group training passed the exam and obtained the MMOG/LE reviewer qualification certificate issued by Odette International.

As the only partner of Odette in the Greater China region, CEDEX has rich experience in MMOG/LE (Materials Management Operational Guidelines/Logistics Evaluation) training and evaluation. Developed by Odette and AIAG, MMOG/LE is a tool for evaluating automotive manufacturing and logistics suppliers, providing guidelines for evaluating logistics processes and driving continuous improvement programs. For nearly 20 years, MMOG/LE has regareded as the "best practice" in the automotive manufacturing industry for evaluating OEMs' supply chain management processes for thousands of Tier 1 and Tier 2 suppliers to improve the quality of material deliveries, and standardizing and digitizing supply chain management.

Network Alliance (NA) Partner PipeChain Group Visits China

4/28/24

From April 22-28, 2024, Hans Berggren, CEO of Network Alliance (NA) partner PipeChain Group, and Mikael Johansson, Director of Growth Initiatives, visited CEDEX's offices in Beijing and Wuhan, and traveled to Ikea's Shanghai office and Volvo's Asia-Pacific headquarters for business development. The main purpose of the visit was to promote the latest business features of the EDI and SCM systems for supply chain management based on Network Alliance(NA) cooperation.

PipeChain Group has been working with IKEA Sweden for nearly 20 years, and on this trip PipeChain introduced the Network Alliance (NA) supply chain solution to IKEA Shanghai. Network Alliance (NA) visited Volvo VCC SLA team for an in-depth discussion, highlighting the AI demand forecasting & demand visualization technology, which was recently launched. The VCC SLA team highly spoke of this as a “Great meeting". 25th April, in Wuhan Office, Network Alliance (NA) members held a group session, where both sides discussed business and technical issues and reached a consensus on current progress and challenges.

In order to enhance the cooperation between PipeChain and CEDEX, our friends were invited to join a local cultural tour for taking a cruise with Zhiyinhao (Friendship) on Yangtze River. CEDEX sincerely hope that this trip can strengthen the cooperation and bring more understanding between two parties.

CEDEX Provides MMOG/LE On-site Training and Consulting Services to Johnson Electric International Ltd.

4/20/24

From April 17th to 19th, MMOG trainers team of CEDEX traveled to Jiangmen City, Guangdong Province to conduct specialized MMOG/LE on-site training and consulting services for Johnson Electric International Ltd. Johnson Electric is mainly focusing on the production of electrical machinery and equipment, and its business scope includes the development, production and operation of micro motors and their parts, molds and fixtures, small hardware, new electronic components, new instrument components, key auto parts and accessories.

This training was requested by their OEM clients, aiming to help the company pass the basic review of MMOG/LE v5. More than 30 people attended this training and more than 40 people were online, totaling nearly 80 employees from the supply chain department participated in the training.

CEDEX is authorized as the mere official partner of ODETTE in China and has rich experience in MMOG/LE training and assessment. Most of trainees considered the training as a great help. MMOG/LE is a tool developed by ODETTE and AIAG to help with continuously development for automotive manufacturing and logistics suppliers. Over the past 20 years, MMOG/LE has evolved into the automotive manufacturing industry's "best practice" for evaluating OEMs' supply chain management processes affecting the quality of material deliveries to thousands of Tier 1 and Tier 2 suppliers, standardizing and digitizing their supply chain management, and helping companies improve operations and sustainability.

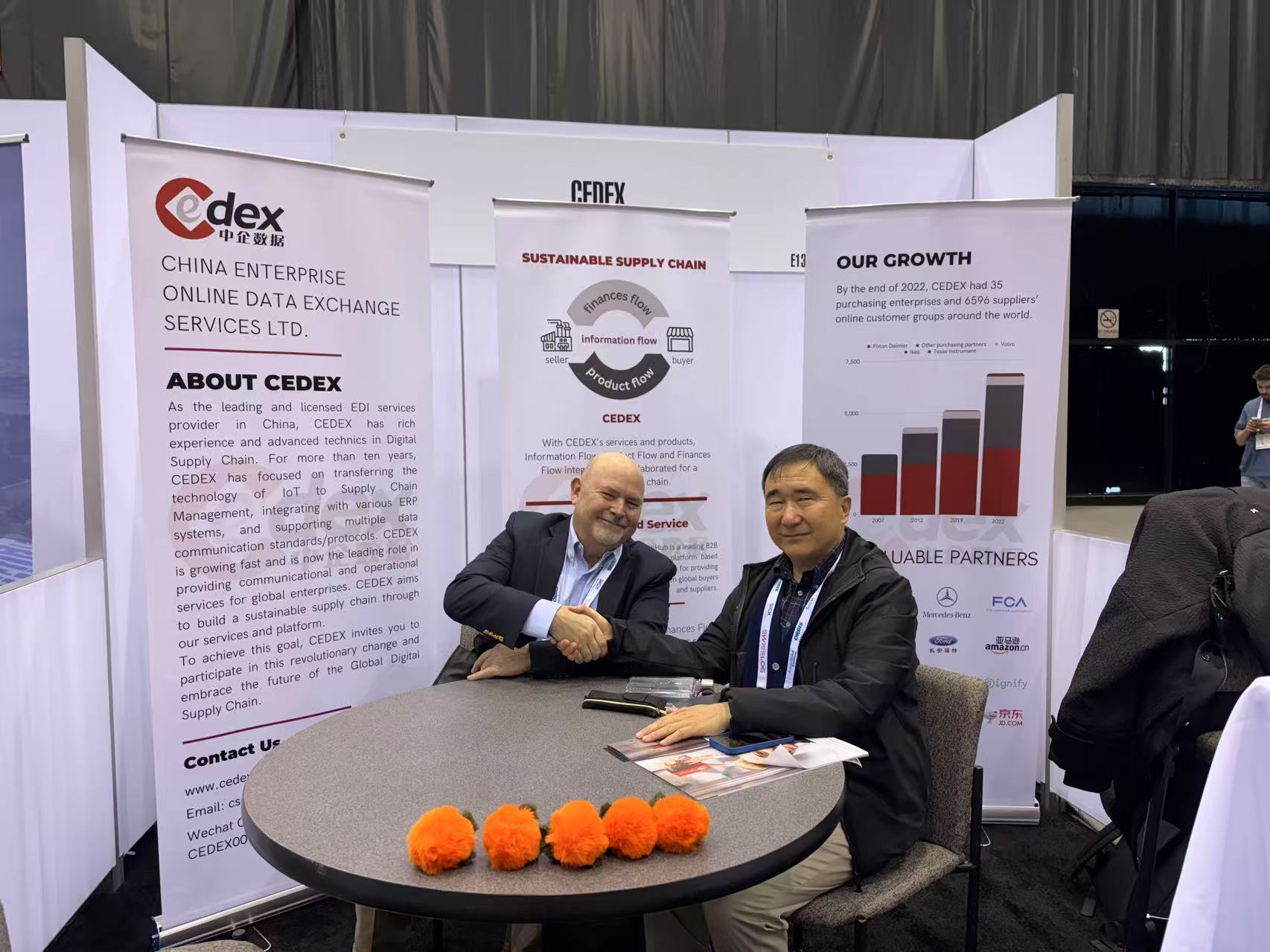

CEDEX joined MODEX 2024

3/20/24

March 11-14, 2024, CEDEX participated in MODEX 2024 in Atlanta.The MODEX conference is organized by MHI(Materials Handling Industry) as one of North America's largest trade shows for the logistics, supply chain and transportation management industries. The show brings together a pioneering 1,175 exhibitors and more than 45,000 industry expert visitors from across the globe in the field of supply chain management, with the aim of sharing the latest logistics and supply chain management technologies and solutions.

During the four days of the exhibition, CEDEX talked with many companies in the supply chain management field. CEDEX targeted to develop locally rooted logistics solutions especially for Chinese companies hosting factories in North America. Currently, CEDEX has successfully become an EDI/API partner for many suppliers, buyers and logistics service providers in the U.S., including well-known companies such as Texas Instruments, Intel, UPS, FedEx and Amazon. CEDEX is now providing services for those manufacturers and logistic service providers to facilitate seamless data interchange and ERP/WMS integration. This has enabled these companies to manage orders, deliveries, and invoicing directly within their own ERP/WMS systems—eliminating the need for third-party portals.

Through MODEX, CEDEX has learned about logistic challenges faced by Chinese invested factories abroad, and has become more confident that through our experience and innovative technology, we can provide technical support for China's manufacturing industry to go localization.

CEDEX Provided MMOG/LE V6 Onsite Training and Consulting Services for Langfang Jinrun Group

1/31/24

January 30th to 31st, MMOG trainers team of CEDEX traveled to Langfang, Hebei to provide MMOG/LE on-site training and consulting services to Langfang Jinrun Group.

Jinrun Group is a leading enterprise in non-standard automation equipment automation production lines, locomotive (train, subway, and light rail) brake systems, medical equipment, electronic products, etc. The company specializes in automotive brake motors (ABS/ESC), motorcycle electronics, general engine generator components, and casting products. The group has an annual sales revenue of 700 million RMB. At the request of customers in the automotive industry, Jinrun Group is required to meet the basic review of MMOG/LE v5 version.

CEDEX is authorized as the mere official partner of ODETTE in China and has rich experience in MMOG/LE training and assessment. MMOG/LE is a tool developed by ODETTE and AIAG to evaluate automotive manufacturing and logistics suppliers. Over the past 20 years, MMOG/LE has evolved into the automotive manufacturing industry's "best practice" for evaluating OEMs' supply chain management processes affecting the quality of material deliveries to thousands of Tier 1 and Tier 2 suppliers, standardizing and digitizing their supply chain management, and helping companies improve operations and sustainability.

Network Alliance visited Swedish Business partners

12/1/23

From 11/22/23 to 12/01/23, after the participation in the Odette 2023 Annual Conference, Mr. Tao Ye and Ms. Ai Yue, VPs of CEDEX, have paid an 8-day working visit to the our Network Alliance(NA)partner, Pipechain Group, in Sweden. During their visit, the NA partners jointly visited several local buyer partners and engaged in business and technical discussions with various departments within Pipechain. This journey took them across half of Sweden, strengthening CEDEX's partnership with Swedish counterparts within the Network Alliance and exploring new business opportunities.

Throughout the visit, the NA partners engaged in discussions with IKEA's business department to gain insights into IKEA's business scale and expansion plans in the Asian market, as well as the future direction of suppliers EDI development.

The NA partners held meetings with logistics and supply chain executives at Volvo, conducted a working session with their EDI team, and had the opportunity to tour Volvo's truck and commercial vehicle groups.

In addition, the NA partners met with the EDI team of the renowned Swedish truck manufacturer, Scania. Scania established new manufacturing base in Jiangsu Rucheng in 2022, with plans with an annual production capacity of 50K units by 2024. CEDEX is expected to explore potential supplier EDI collaboration opportunities with Scania in the Chinese market.

CEDEX obtained 3 copyrights in 2023

11/29/23

In 2023, CEDEX has obtained three copyrights issued by the National Copyright Administration of the People's Republic of China. The softwares are: Long Distance Sorting Supply Cloud Service Platform [abbreviation: CeA-LDJIS] V1.0; Spot Supply Chain Cloud Service Platform for Electronic Manufacturing Industry [abbreviation: CeA-Store] V1.0; and Container Loading Software [abbreviation: CeA-CLP] V2.0 All softwares are independently developed and upgraded by CEDEX, and have been put into use with remarkable market response.

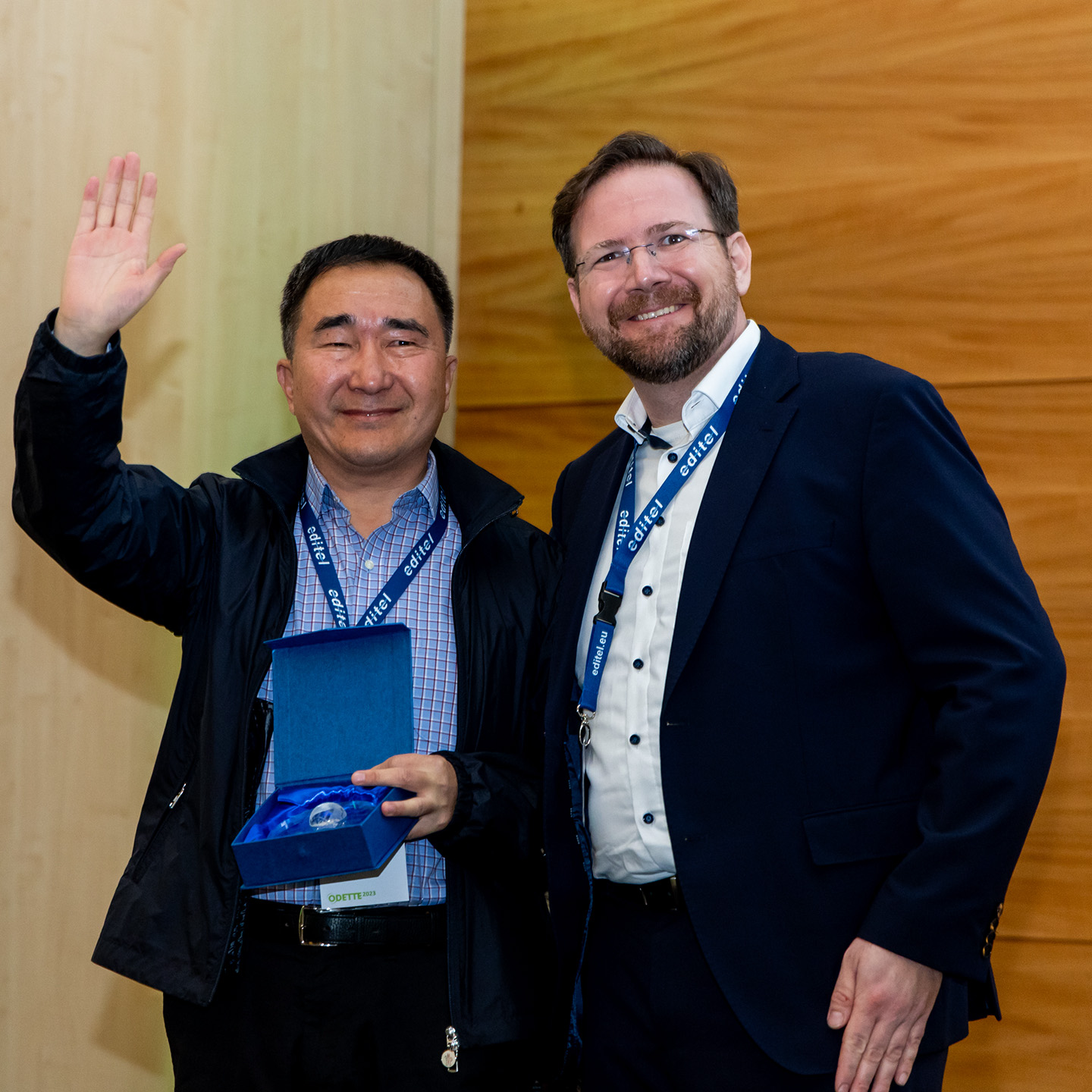

CEDEX was awarded as The Best Service Provider of Odette 2023

11/25/23

On November 20-21, 2023, the 22nd Annual Conference of Odette was held in Berlin. This year's exhibition theme is "Still Building Solutions for Sustainable Supply Chains", and CEDEX with our Swedish partner Pipechain are participating in the exhibition together.

Since 2006, CEDEX has been cooperating with Odette (Organisation for Data Exchange through Tele-Transmission in Europe.) for 17 years on the Material Management Operations Guide/Logistics Evaluation (MMOG/LE) industry standard for the automotive manufacturing supply chain.

The MMOG/LE web-based version of the review platform MMOG.np now serves thousands of Chinese automotive suppliers. Benefiting from the vast market opportunities in China's automotive manufacturing industry and customers' trust in China's automotive industry, CEDEX was honored with the "The Odette International Awards 2023 In recognition of outstanding contributions" at the Odette 2023 Annual Meeting. Together with the 7-member expert group that drafted the MMOG/LE v6 version during the outbreak, the 4-member specialist group that drafted the standard API for the EDI of vehicle logistics, and representatives of the three companies that formulated the OFTP2 standard for the secure transmission of Internet data, we were awarded the "2023 Award of the Year", and CEDEX won the "Best Service Provider Award."

Mr. Mingguang Cheng, Founder and CEO of CEDEX, with two young leaders in their 90s, Tao Ye and Ai Yue, attended the award ceremony and accepted the medal presented by Robert Cameron, head of the logistics department of VDA Germany and Chairman of Odette, on behalf of Odette.

CEDEX held MMOG/LE v6 Training Session (Chinese) in Wuhan

9/28/23

2023 is the first year of the official launch of the global MMOG/LE v6. To better meet the review requirements of the OEM customers, CEDEX held the 2023 Global MMOG/LE v6 training session (in Chinese) in Wuhan from 22nd-23rd September 2023.

CEDEX held the session in a small group of less than ten people so the participants could practice the MMOG evaluation platform online. Representatives from six suppliers, including Shanghai GKN Drive Shaft Co., Ltd., Luzhou Changjiang Machinery Co., Ltd., Chongqing BAIC Molding Technology Co., Ltd. and one MMOG/LE business manager from Changan Ford Motor have participated in the training. Through the session, the reviewers had a deeper and more comprehensive understanding of the MMOG/LE review standards, hands-on with online review practices, and had in-depth exchanges with customer representatives. All eight reviewers who participated in this small-group session passed the exam and obtained the MMOG/LE reviewer qualification certificate.

MMOG/LE is an industry standard developed by Odette and AIAG for assessing material management operations in the automotive manufacturing supply chain to ensure timely delivery and constitutes a "QCD" equilateral triangle with IATF16949 and manufacturing cost for buyers to select suppliers. Over the past 20 years, MMOG/LE has fully absorbed the experience learned from material management in the auto parts industry and iteratively launched the 6th version, which has become "best practices" for material delivery in the global automotive manufacturing industry. MMOG/LE has been used by OEMs and Tier 1 suppliers to evaluate Tier 1 and Tier 2 suppliers to ensure the material quality and delivery. The practice has standardized and digitized its supply chain management to help the entire supply chain members make "continuous improvements" to increase supply chain efficiency, reduce costs, address risks and challenges, and achieve sustainable development.

CEDEX Provided MMOG/LE V6 Onsite Training and Consulting Services for BorgWarner

8/18/23

August 14-17, 2023, CEDEX training instructors have joined BorgWarner Suzhou Industrial Park office to provide on-site training and consulting services for MMOG/LE(Materials Management Operational Guidelines/Logistics Evaluation) V6 version. BorgWarner is a well-known American automotive and e-mobility supplier, with its main business focusing on turbocharging systems, mousse systems, transmission systems, powertrain systems, fuel injection systems, etc., BorgWarner's headquater locates at Michigan, U.S.A. The company entered China in 1993, and for embracing China's fast-growing new-energy automobile market, the company has been actively expanding clean and efficient automotive technologies.

CEDEX is appointed as the mere official partner of ODETTE in China and has rich experience in MMOG/LE training and assessment. MMOG/LE is a tool developed by ODETTE and AIAG to evaluate automotive manufacturing and logistics suppliers. Over the past 20 years, MMOG/LE has evolved into the automotive manufacturing industry's "best practice" for evaluating OEMs' supply chain management processes affecting the quality of material deliveries to thousands of Tier 1 and Tier 2 suppliers, standardizing and digitizing their supply chain management, and helping companies improve operations and sustainability.

CEDEX Provided MMOG/LE V6 Onsite Training and Consulting Services for Compal Electronics

7/28/23

CEDEX has years of experience in MMOG/LE training and assessment, and as the mere official partner of ODETTE in China, has provided MMOG/LE V6 onsite training and consulting services for Automotive Division of Compal Electronics Technology (Kunshan) Co. Compal Electronics Technology (Kunshan) Limited. Compal Electronics is the world's second largest notebook computer manufacturer. The headquartered of Compal Electronics is located at Taipei City, Taiwan, and the manufacturing facilities are in Kunshan City, Jiangsu Province. The campus is equipped with three notebook computer manufacturing plants, one video product manufacturing plant and one automotive electronics manufacturing plant. A total of 48 Compal supply chain managers participated in the training program, with nine of them attending remotely from the Taipei headquarters. Compal Electronics is in the process of upgrading from a Tier 2 automotive supplier to a Tier 1 supplier, and according to the OEM customer requirements, the company need to pass the full MMOG/LE v6 review.

MMOG/LE (Materials Management Operational Guidelines/Logistics Evaluation) is a tool developed by ODETTE and AIAG to evaluate automotive manufacturing and logistics suppliers. Over the past 20 years, MMOG/LE has evolved into the automotive manufacturing industry's "best practice" for evaluating OEMs' supply chain management processes affecting the quality of material deliveries to thousands of Tier 1 and Tier 2 suppliers, standardizing and digitizing their supply chain management, and helping companies improve operations and sustainability.

CEDEX joined CES 2023 in Las Vegas

1/14/23

CES (The Consumer Electronics Show) is one of the world's largest electronic technology exhibitions. Since it was first held in New York in 1967, CES has been leading the latest technology trends in the electronics manufacturing industry for more than 50 years. 2023 CES was held in Las Vegas in January 2023, with daily traffic of more than 15,000 people. More than 3,700 exhibitors have been divided into 24 themes, such as 5G and smart home. We found that Chinese companies were exhibiting under each theme.

The major future technology trends presented at CES focused on XR (VR, AR and other virtual reality technologies), smart electric cars, smart homes and other directions. Developers of the metaverse went a step further by making smell and touch as part of the virtual world experience; car manufacturers stepped out of the traditional manufacturing industry and added new services such as intelligent voice and big data computing to the driving experience; smart homes also proposed services more tailored to customer health. Through a large number of case studies, we can feel that technology companies are trying to solve one of the major needs of consumers - interaction and feedback - through constantly evolving technology. The future of technology will focus more on the interaction between electronic technology and consumers as well as social life.

Under these circumstances, the concepts of "digital supply chain", "digital twin" and "logistics metaverse" proposed by CEDEX at CES 2023 are in line with the theme of the show. CEDEX hopes to provide customers with high-quality EDI services and realize the unification of information flow, logistics and capital flow between buyers and sellers. Therefore, the information flow in the virtual world, as well as the logistics and capital flow in the real world, can become a pair of "digital twins". The interaction and feedback are completed in the virtual world, thus reducing the cost and inventory in the real world. In addition, CEDEX’s EEEU loading project has received a lot of attention. Some well-known manufacturers came to our booth to ask about the details of the loading project and said they all had similar needs. This also boosted the confidence of the project's development and sales team.

2023 was the first time CEDEX to exhibit at CES. through the show, we gained a more detailed understanding of our existing customers, such as Leedarson and Texas Instruments. CEDEX has learned from the sales department about market segments, customer composition, and the upstream and downstream of the commodity market. With the change of covid policies, Chinese exhibitors at CES are gradually returning, and there were a large number of Chinese exhibitors at this show. Talking with dozens of Chinese exhibiting manufacturing companies during the show, we found that they all used Texas Instruments' electronic components in one way or another. During the communication with many Chinese and overseas exhibitors, CEDEX also learned about some leading companies in China's electronics manufacturing industry. This has laid the foundation for further market development.

Through this exhibition at CES, CEDEX is convinced that the digital supply chain is the future direction of logistics management and the way to connect to the future world. The communication with many exhibitors also broadened our business horizon and helped us prepare the business plan in the coming year.

Copyright was issued for CeA-SRM and CeA-oftp2

12/21/22

With the deepening of supply chain digitization in different industries, CEDEX continues increasing the input of research and development . To maintain the highest quality service, CEDEX has upgraded the supplier relationship management software (CeA-SRM) V5.0, and the Internet secure data transmission software (CeA-oftp2) V2.0. Both software have obtained the computer software copyright registration certificate from the National Copyright Administration of the People's Republic of China. Both software have been put into use, and have won unanimous praise from customers.